ATLANTIS C4S

ATLANTIS C4S - Mepal

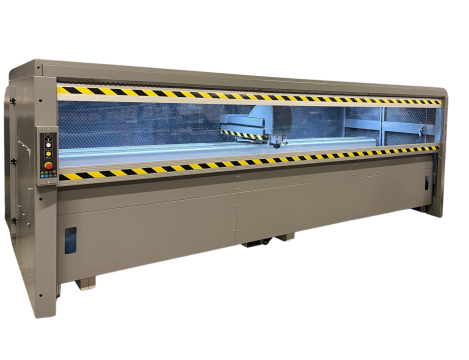

The ATLANTIS C4S – 4 Axes, numerically controlled work centre with a 4-metre working range.

Machining center for aluminum, PVC, light alloy and steel profiles with the ability to machine parts on 3 faces.

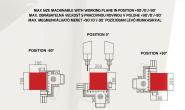

C4S has a pneumatic rotation working table: +90°/0°/90°, intermediate angles are obtained by mechanical stops;

C4 PLUS has a CNC controlled electronic rotation table, from -90° to +90°.

Spindle speed adjustment from 2800 to 18000 rpm is controlled by a frequency inverter.

Computer Numerically Controlled Interpolation of X and Y. Axis X, Y and Z movements utilize digital brushless motors.

The unit come complete with 6 pneumatic double acting clamps for material fixturing and optionally with an automatic tool changer and pneumatically operated left and right stops.

Tool diameter correction is compensated by the software.

The machine can be equipped with a frontal protection or a complete cabin on request.

Automatic clamps movement with the spindle to avoid positioning error can also be requested.

The automatic tool changer can hold up to 11 tools, 1 of them can be an end mill (max Ø 160 mm).

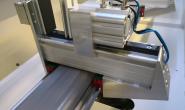

A retractable enclosure protects tools from chips and dust produced during the machining process.

STANDARD ACCESSORIES:

Electrospindle HSD ES330 4.5 kW 0-18000 RPM

6 pcs vices with manual displacement

1 pc venturi lubrication nozzle on the spindle

Rapid tool changer with ISO30 cones

Spindle cooling with electric fan

Numerical control

PC with monitor

Mouse and keyboard

Windows 10 operating system

Serial and Ethernet interface for connection

with barcode reader and to LAN

Operator console separate from the machine

On-board control panel

Air gun with spiral hose

Segmented spanner for dismantling cones

Machine documentation

CE certificate

Use and maintenance manual

CNC manual

Electrical and pneumatic diagram

Safety system with opto-electronic barriers

ISO Standard DXF to Macro programming language

Communication system for remote control with Ethernet or WiFi connection

OPTIONS

Electronic rotation of the working table

Automatic tool changer with 11 positions

Tool length measuring system

Front guard

Integral cabin

Clamp kit

Tools kit:

5 Pieces ISO30 ER32 tool holders

5 Pieces milling cutters

End milling kit for ISO30 complete with:

ISO30 tool holder for end mill

End mill diameter 160 mm

Counter-balanced threading tap ISO30 M3-M10

Automatic positioning of the clamps managed by the CNC

MAX SIZE MACHINABLE WITH WORKING PLANE IN POSITION +90°/0°/-90°

X axis 4200 mm

Y-axis 570 mm

Z-axis 300 mm

Axis I 180°

Spindle Speed 280-18000 RPM

Spindle power 4.5 kW (8 kW on request)

Max. axis speed:

X=60 m/min

Y=45m/min

Z=25 m/min

I= 3 m/min

Max. disc cutter diameter 160 mm

Dimensions

Length 5400 mm

Width 2400 mm

Height 2000 mm

Type Cone ISO30

Tool change 11 positions (on request)

Number of reference stops 2

Vices 6 manual

Automatic vices Displacement with

spindle (on request)

Cooling Electric fan

Tool lubrication 1 nozzle on spindle

Oil tank capacity 5 litres

Operating pressure 7 bar

Air consumption 35 Nl/min

Power consumption at 400 V 8 kW

Required current 20 A

Maximum machinable cross-section 200x200x4000 mm