Processing and cutting center for PVC profiles

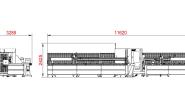

Processing and cutting center for PVC profiles - KABAN - SB 3011

• It makes processing and cutting operations of PVC profiles.

• Precise measuring thanks to linear measurement system.

• Automatic greasing system.

Control Panel

• User-friendly operating system compatible to all joinery and optimization programs.

• Minimum waste, maximum production algorithm.

• The wastes are optimized automatically in cutting list.

• Parameters are set easily.

• Different profiles and hardwares can be configured and optimized.

• Periodical maintenance reminder function.

• 17" LCD Screen.

• USB input.

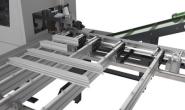

Profile Processing Unit

SB 3010

• The driller processes on horizontal axis and distance between 0-330° degrees.

SB 3020

• It processes with 7 drillers on horizontal axis and distance at 0°-45°-90°-135°-180°-225° and 270° degrees.

Profile Unloading Unit

• Output robot conveys the cut profiles on conveyor automatically.

• The operator sticks the barcode on cut pieces to prepare for next operation.

Profile Loading Unit

• Profile loading capacity: 9 profiles.

• Loading capacity can be increased optionally.

• Automatic profile recognition feature on profile conveyor and positioner.

• Profile Length: Minimum 850 mm – maximum 6.500 mm. (optionally eternal)

• Warning system to prevent wrong profile loading.

Profile Cutting Unit

SB 3010

• It cuts with 3 saws at 45° and 90° degrees.

SB 3020

• It cuts with rotating saw between 22,5°-157,5° degrees.