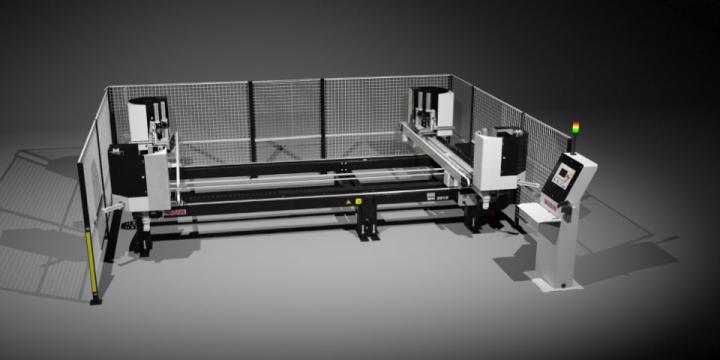

Four head welding machine with PC

Four head welding machine with PC - KABAN - MK 2010 PC

General features:

- 90° welding of four corners of PVC profiles.

- Tolerance system to minimize measuring faults.

- Automatic greasing system.

• User-friendly operating system compatible to all joinery and optimization programs.

• Parameters are set easily.

• Different profiles and hardwares can be configured and optimized.

• Periodical maintenance reminder function.

• Welding by inserting the dimensions manually without using barcode reader.

• Operation with Cf card.

• Barcode reader.

• Has ethernet connection.

• Practical teflon change thanks to roller system

• Saving of time thanks to practical mould change system.

• Axis positioning 0,1mm sensitivity.

• Cutting and welding tolerances distributes equally to 4 corners.

• X and Y axis automatic positioning.

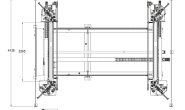

Machine Dimensions:

Length (L) 4950 mm

Width (W) 5200 mm

Height (H) 1930 mm

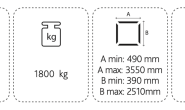

Weight 1800 kg

Air:

Operating pressure 6-8 bar

Air consumption 64 l/min

Electricity:

Voltage 400V (L1-L2-L3-N-PE) 50/60Hz

Power input 11 kW

Weldable Profile Dimensions:

(a) Maximum 130 mm

(a) Minimum 40 mm

(h) Maximum 210 mm

Welding Dimensions - Frame:

(a) Minimum 490 mm

(A) Maximum 3550 mm

(B) Minimum 390 mm

(B) Maximum 2510 mm

Screen:

Windows PC

Hungarian language

Communication:

Manual input of parameters on Windows screen

CF memory card (2000 parameters)

Barcode reader

Control:

Mitsubishi CNC Control Unit